Deep draw metal stamping is a highly specialized process that shapes flat sheet metal into a three-dimensional component with a smooth surface finish and significant depth. Used across many industries, such as agriculture, automotive, medical, and telecommunications, deep draw metal stamping is a popular choice for those wishing to create custom metal parts and components. Let’s take a closer look at the deep draw metal stamping process and the advantages it can offer with the right partner on your side.

The Deep Draw Metal Stamping Process

Design

The key to a successful product is to be prepared, so you must begin the deep draw metal stamping process by planning your design. At HTT, we specialize in upfront design consultations to streamline manufacturing requirements and ensure we meet your precise requirements. This is a key differentiating factor that sets us apart from the competition because it demonstrates our commitment to ensuring your product matches your vision and precise requirements.

Design consultations are an essential part of creating a successful and accurate final product. In addition to reviewing and analyzing the design of the part to better optimize it, you will also review material selection, which generally makes it easier to manufacture the part. These design consultations can also mitigate manufacturing challenges, which can save costs and time in the long run, supporting your bottom line.

Prototype

Next, a prototype, or sample product, will be created in order to ensure that it performs as expected and its design is effective. This allows you to eliminate any potential problems and make sure the finished product will be accurate. At HTT, our team prioritizes your needs at every stage, including prototyping. With our start-to-finish support, we can ensure that your custom metal part is created accurately and to your precise specifications, even with the most complex geometries. Our expert prototyping capabilities enable us to eliminate issues upfront, which allows us to streamline manufacturing, thus saving you time and money.

Production

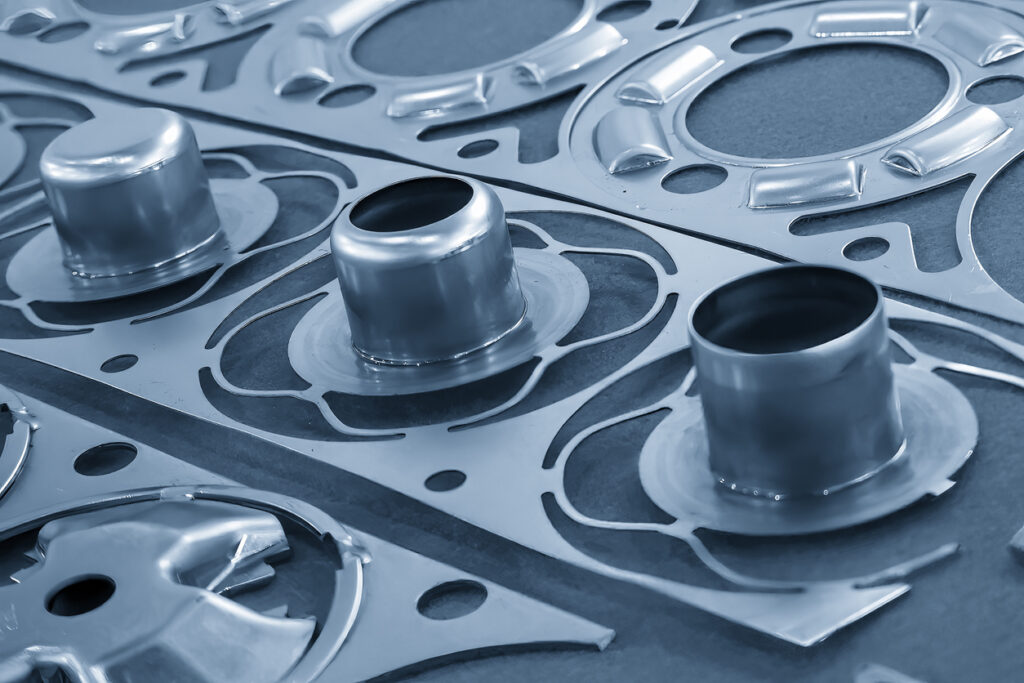

Once the prototype has been approved, production will begin. Our team is able to efficiently transform your custom metal parts into premium deep drawn dies with a draw depth of up to 6”. With our advanced equipment, we can create parts with a coil thickness of .002” to .250”, bar stock thickness of .125” to 3.75”, and widths of .25” to 30.00”.

You might also consider high-volume production runs for your deep draw metal stamping product because it can save you both time and money. With high-volume production runs, your deep draw metal stamping partner produces a larger amount of products. This is advantageous because you don’t have to wait for more batches of your product to arrive. Those delays can be costly and frustrating, so high-volume production runs allow you to maintain satisfactory inventory levels. You can also decrease cost by reducing the number of set-ups and save on shipping costs when receiving larger amounts of products in one order, further enhancing the value of your order.

HTT is able to accommodate high-volume production runs because we have more than 160,000 square feet of space dedicated to deep drawn metal stamping, metal stamping services, metal fabrication, and other value-add services, complete with more than 25 stamping presses. Choosing a valued and reliable partner like HTT for your production needs is essential.

Quality Assurance

Finally, your deep draw metal stamping partner should inspect the final product to ensure it meets your precise specifications. This quality assurance demonstrates your partner’s commitment to producing the custom metal parts that best suit your needs. With our engineering-driven team and cutting-edge technology, HTT consistently produces custom metal stamped components and assemblies that exceed our customers’ expectations. As an ISO 9001- and IATF 16949-certified company, HTT ensures the highest quality while saving time and optimizing costs. With our end-to-end project management and expertise, we can assure you that your products will match your exact needs.

The Advantages of Deep Draw Metal Stamping

Now that we understand the deep draw metal stamping process better, let’s investigate why it’s so popular with customers who want custom metal components and assemblies. What are the advantages of deep draw metal stamping?

Speed

Firstly, deep draw metal stamping allows for more precision and efficiency, so you don’t have to worry about wasting time fixing unnecessary errors during production. The process is fast and you are able to move on to the next step of the manufacturing process without frustrating delays. This enables you to get your product to market faster, saving you time and money.

Highly Precise

With deep draw metal stamping, you can achieve extreme precision, even with parts that have complex geometries, and you can also achieve tight tolerances. This serves to ensure accuracy so that the part matches your precise specifications. Deep draw metal stamping is also extremely repeatable, which allows for high-volume production runs without sacrificing the quality or consistency of your products.

Cost-Effective

Deep draw metal stamping is much more cost-effective than other processes, like casting. As previously mentioned, with this process you are also able to achieve high-volume production, while maintaining quality. This saves you time and money and enables you to get your product to market faster. Utilizing a turnkey partner like HTT also saves you money with our other value-added services, like powder coating, metal fabrication, robotic welding services, and more. With our end-to-end supply of services, you can save money while also ensuring the very best quality for your products.

Versatile

Deep draw metal stamping is effective with a variety of materials, making it a very versatile process. For example, this process can be used with steel, aluminum, copper, brass, and more. Your manufacturing partner is able to customize your part to meet your exact needs and the deep draw metal stamping process also typically produces parts that are strong and durable.

Choose HTT for Quality Deep Draw Metal Stamping Today

For high-quality deep draw metal stamping services, turn to the expert team at HTT. We prioritize your needs at every stage of the process, and our turnkey capabilities ensure that we produce custom metal components and assemblies that match your exact specifications. In addition to our comprehensive metal stamping services, we also offer tool and die manufacturing, wire EDM services, and much more. We also have extensive experience serving a variety of industries, such as agriculture, automotive, construction, and more.

Since 1985, HTT has been a trusted and reliable partner for custom metal parts. If you’re looking to enhance the quality of your deep draw metal stamping product, contact us today.